Considering an alternative Lean approach to ISO's Harmonized Structure

Progress indicator

Sucilla Harrikissoon CQP MCQI examines the importance of a Lean approach to implementing ISO’s Harmonized Structure.

The International Organization for Standardization (ISO) has been a vanguard in developing management system standards (MSS) for a broad spectrum of organisational systems, which have been recognised and accepted by stakeholders globally.

ISO recently communicated the Harmonized Structure (HS) "to enhance the consistency and alignment of ISO management system standards by providing a unifying and agreed upon Harmonized Structure (HS) with identical core text, common terms and core definitions."

However, even though the HS seeks to unify "core text, common terms and core definitions,” the content of the now HS requirements are still repeated in text, in each individual standard. This leads to the question – if there is one set of unified text, and terms definitions, why couldn’t there have been one document (call it a standard, if you will) that outlines the unified content referenced in the HS? Why repeat the HS in each standard?

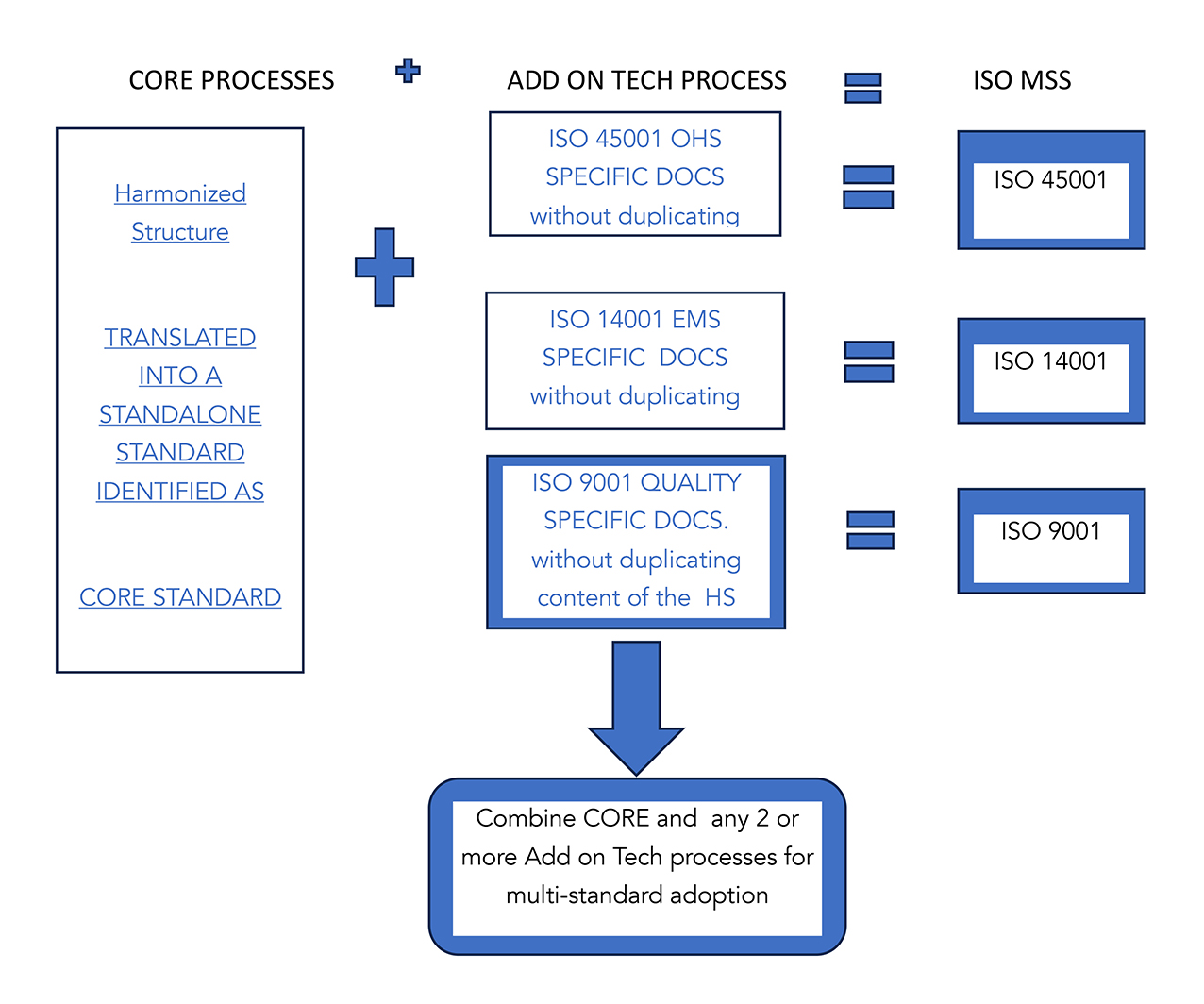

Considering the HS is intended to enhance the current levels of compatibility between any existing management system standards, development of the HS could have been further enhanced with a few additional steps:

- Extract content requirements which now makes up the HS in Type A and Type B (independent) and which are currently repeated in each standard.

- Place this HS content into a separate document – an MSS CORE/Foundational Requirements.

- Use content that remains after extraction of the HS from each standard, to form a separate, smaller addendum, outlining technical requirements that organisations can choose to adopt once the HS is implemented. For example, with ISO 45001, when the HS is removed, you would remain primarily with requirements specific to worker participation, Incident, nonconformance, and corrective action.

Adopting these additional three steps could result in significantly leaner standards now that all HS content is removed from each individual standard.

With the current structure of the HS and its intent being to unify common text, terms and definitions that have a common unified outcome, inevitably, as with any harmonisation exercises, processes would be trimmed, and waste in any form would be reduced.

As quality practitioners, we are all aware that a lean approach is beneficial for minimising or eliminating waste, so the questions that emerge for me are: are we overproducing and over-processing content within the standards? Can we make standards leaner to reduce complexity, extraneous content, and cost for adoption while simultaneously retaining its intended value?

"Are we overproducing and over-processing content within the standards? Can we make standards leaner to reduce complexity, extraneous content, and cost for adoption while simultaneously retaining its intended value?"

Has the time come for us in the quality profession to reassess existing patterns of how we do things without compromising the intended outcome? Is there on the horizon, a shift that could see organisations pursuing the HS CORE to achieve a new general certification and then go for add-ons/addendums for technical conformance?

Why continue to have auditor/training courses for various ISO standards with each course covering the same HS content that increases the length of the course and cost of training? Is this another type of waste being generated? Are the ways we are transferring knowledge on quality inhibiting adoption?

Can exploring these questions help navigate the quality profession on its own path to practice what we preach – continual improvement?

I encourage the quality community to collectively explore these questions.

Furthermore, Lean principles should also be considered by decision-makers during the development and revision of standards. After all, standard development is also a process.

Reducing overproduction of content and decreasing complexity of standards can be the catalyst to encourage adoption of best practices and increase opportunities to trade globally, especially SMEs.

If we subscribe to the view that the intent of standardisation of systems can demonstrate reliability, then the words of the software engineer and scientist Edgar W Dijkstra will be worth remembering: “Simplicity is the pre-requisite for reliability.”

Conclusion

Having a CORE HS standard for ISO standards represents a change in current approaches towards greater ISO systems integration and coherence.

By embracing this approach, ISO and national standards bodies can remove duplicated content.

It is my hope that this article initiates meaningful discussions among the quality community on the methods that can be used to achieve a Lean approach to MSS standardisation, and implementation using the following framework depicted in Figure 1 below:

A Lean Approach to ISO 's Harmonized Structure for ISO Management System Standards Implementation – Sucilla Harrikissoon ©

Read more content like this

Jessen Yeoh CQP MCQI, an IRCA Principal Auditor and a principal advisor at P Excel Advisory in Melbourne, Australia, draws on ISO 9001 to outline the ‘hierarchy of improvement’.

Apply to join the CQI

Start your application and join the only chartered body dedicated to quality.

Quality Careers Hub

Exclusively for members, the CQI’s Quality Careers Hub is designed for every career stage. So whether you’re just starting out, ready to move on or up, or looking to build on your experience, there are many ways to progress.