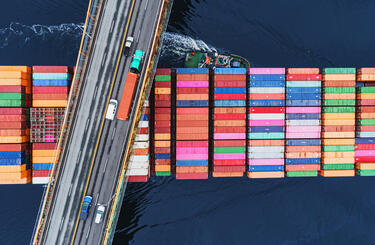

Can quality bring order to fragile supply chains?

Supply chains are buckling under the strain in uncertain times - has quality a part to play in bringing order to the forces of change? Here, Alexander Woods, the CQI's Policy Manager, discusses the pressures that the supply chain faces, and calls on quality professionals to remain proactive in supporting their organisations.

Global supply chains have faced significant disruption in recent years. The management publication, Harvard Business Review reported that Covid-19, shifts in international relations, and the escalation of the Russo-Ukrainian War, have all exposed the fragility of supply chains. Lockdowns, travel restrictions, and social distancing measures implemented to contain the spread of Covid-19 caused significant disruption to the production and distribution of goods and services. Manufacturing facilities operating at reduced capacity, if at all, led to shortages of critical supplies and products. The reliance on global sourcing became a vulnerability as companies struggled to meet demand.

The 'new normal'

Covid-19’s impact on ways of work is lasting. While remote or hybrid working, decentralised workspaces, and diverse work patterns were far from unique in 'pre-Covid' times, the pandemic accelerated and exacerbated drastic changes in workflow, workforce, and workplace. Consumer needs and expectations have also long been shifting. Rapid changes in technology, evolving consumer preferences, and the rise of e-commerce have disrupted traditional supply chain models and revealed how vulnerable they are to disorder. Consumers expect fast delivery times, greater product variety, and seamless omnichannel experiences. They want greater transparency, and commitments to sustainability from the companies they buy from.

The impact on trading

The United Kingdom’s withdrawal from the European Union has resulted in trade barriers, customs checks, and regulatory changes across borders which previously did not exist. These disruptions continue to cause delays in the movement of goods, increased administrative burdens, and added complexity to supply chain operations, most especially in the UK.

Businesses have been forced to re-evaluate their existing supply chains. They cannot rely solely on their traditional supply chain networks, as disruptions have shown the need for diversification to mitigate risk. Many companies have explored nearshoring or reshoring options, reducing their dependence on distant suppliers, and ensuring greater control over their supply chains.

All these challenges have been exacerbated by long-term underinvestment in supply chains. Governments and businesses have focused on stimulating consumer demand and propping up economies, often at the expense of investing in production and supply capacity and infrastructure. This lack of investment has left supply chains vulnerable to shocks and less resilient in the face of disruptions.

This disruption is by no means behind us.

According to a report from CapGemini, a consultancy, on the 2023 World Economic Forum Annual Meeting, supply chain represents the top risk to business growth in the next 12-18 months.

And the professional services network, KPMG, predicts supply chain disruptions to continue through 2023 and beyond, the key trends for 2023 including:

-

scepticism about cross-border trade cooperation

-

increased cybercriminal activity

-

turmoil in access to key materials

-

changing manufacturing footprints

-

evolving retail and distribution supply chains

-

accelerated technology investments

-

scrutiny of scope 3 emissions (indirect emissions that occur in an organisation’s value chain).

Organisations may wish to focus on strategies and plans to address these trends, and on ensure they have the capability and resources to do so effectively. Quality professionals, already involved in supplier selection, evaluation, and assurance, have a key role to play.

As organisations increasingly look to novel and disruptive digital technologies to improve the effectiveness and efficiency of supply chain management, there is an emerging role for quality professionals for assuring their use. Adopting new technologies introduces new risks. Organisations must be able to assure interested parties that the correct digital tools are being procured and deployed. Risks associated with their use and integration must be identified and controlled. And the data used or provided must be accurate, relevant, complete, and secure if it is to be of value. Herein lies an evolution of the role of the quality professional, in assuring the use of digital technologies. This is the subject of our recent research projects on Quality 4.0 and the future of assurance.

As supply chain disruptions show no signs of abating, quality professionals must remain proactive in supporting their organisations in the governance, assurance, and improvement of strategies to build and maintain resilient supply chains. Supplier management, contingency planning, data-driven decision-making, and the effective leveraging of digital technologies are critical roles for the quality professional. These will enable their organisations to proactively address challenges, minimise disruptions navigate the challenges and drive success in supply chain management.

Take the course

Acquire the practical skills required to manage supply chain risks and encourage suppliers to take a process based approach to drive improvement.