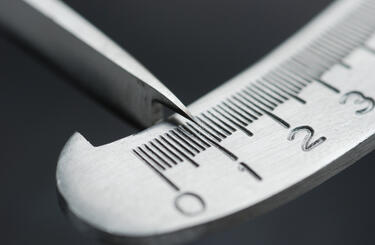

Calibration – an essential process

Progress indicator

IRCA-certified Lead Auditor Gautam Kumar Maiti PCQI examines the importance of ensuring correct calibration of all instruments at the start of a project.

Calibration is an essential subject in the field of construction, especially in India. Here, people may possess knowledge of it, but do not use it fully, while others lack the necessary knowledge.

Calibration is an activity that should be carried out at the preliminary stage of each project. Unfortunately, in India especially, this is being ignored. Rather than ensuring calibration as per national or international standards, many people are in the habit of simply saying that something has been calibrated by the factory. In spite of knowing the requirements, people are choosing the convenience of the wrong practice.

Even qualified engineers and renowned construction companies in India are taking the subject of calibration lightly, despite the same companies and their engineers acting completely differently when working outside of India.

Ensuring calibration should be the first task at the start of every project. Whether starting a civil or mechanical job, or doing some instrumentation job, calibration is an essential, inherent process.

Why is calibration important?

During my 37 years of working in quality assurance and quality control with various national and international companies, I have encountered people who do not know what calibration is. Even worse, some who know the need for accurate calibration still disregard it.

All measuring instruments should be calibrated as per the requirements set out in ISO/IEC 17025:2017 General requirements for the competence of testing and calibration laboratories.

Why do we require calibration? Let me explain with an example. Imagine you are flying abroad carrying the permitted luggage allowance. At the airport check-in counter, however, you are told your baggage is 5kg over weight and you will be charged $100 per kg. Upon investigation, it is discovered that the baggage scales have not had their calibration checked for two years. However unknowingly, the airline has been cheating its customers. We should be confident that calibrating tools and equipment are measuring correctly – in this case, weighing the way they are supposed to.

"Ensuring correct calibration has implications all over the world. From visiting a shopping mall to attending a specialist hospital, everywhere we go, we will come across measuring instruments."

Benefits of correct calibration

There are many benefits to knowing that the calibration in a process is correct:

- Proper calibration reduces manufacturing error, which has a cost benefit in any project.

- Calibration keeps processes safe. For example, when measuring parameters such as electric current it is important that the quantity being measured is accurate to maintain product safety.

- It helps ensure accurate measurements, which are fundamental to the quality, safety and innovation of most products and services we rely on every day. Few people realise the critical role and importance of calibration in their daily lives.

Relying on factory calibration

Every measuring instrument should perform within the limit of accuracy. If the accuracy of an instrument is outside the expected limits of accuracy, it should be calibrated back to an acceptable performance level. If the equipment is non-adjustable, however, the deviation or measurement performance should be recorded and sent for recalibration.

Factory calibration means that the equipment’s performance is certified as per factory specification. However, as long as factory calibration is not supported by a traceable master calibrator, there is no way of knowing that the calibration is accurate. So, if a factory calibration certificate does not show any traceability, we shall discount that certificate.

There are a few manufacturers that provide a calibration certificate traceable to a master calibrator, or their calibration laboratory is accredited by a national or international agency – for example, the National Accreditation Board for Testing and Calibration Laboratories in India, or UKAS in the UK.

Conclusion

Ensuring correct calibration has implications all over the world. From visiting a shopping mall to attending a specialist hospital, everywhere we go, we will come across measuring instruments. If we are unaware of the importance of calibration, we could face detrimental issues; a small variation in any number of areas could have significant consequences.

Read more about calibration

It’s critical to maintain the measurement accuracy of test instruments if they are to work properly, explains Steve Winder, Service Sales Manager at Calibrationhouse, which provides UKAS accredited calibration services for all types of electronic equipment.

Quality World

Get the latest news, interviews and features on quality in our industry leading magazine.