Quality motivation

Progress indicator

Sponsored article: Paul Vaughan, Lead Quality Manager in Projects at Siemens talks about how his company is working to improve workforce involvement and motivation to use quality tools.

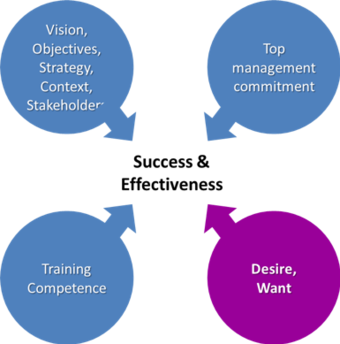

Thanks to our inspirational quality pioneers, both past and present, we have some truly great quality tools at our disposal. A significant number of which have been or are being used at Siemens. Like the fire triangle, we recognise that there are a number of key factors, aside of the tool itself, that must happen for any of these tools to be an effective success in their implementation and continuing improvement. There are obvious ones, like the need for the initiative to deliver on the organisation’s vision, objectives and strategy, in the context of the direction of the business and in the best interests of all stakeholders; the need for the workforce to be competent in its tasks; and the process needs to be led with the full commitment and backing from the top management. Although one would think it is obvious, the omission of the following is arguably one of the biggest contributors to a failed initiative i.e. there must be a real desire in the workforce to want to use/to do it.

Quality, both good and bad, can be associated with behaviours and habits. But it is not an instinct. A baby taking its first steps is a naturally instinctive process. But it can also be driven by an urge to ape its elders, exploring, and processing images and data. So the question is: How do you go about creating such a desire in the workforce? A want to take those first step(change)s.

This was a very real enigma that we faced in Siemens. We have the good fortune of having a comprehensive and dynamic business management system (BMS). Over the years it has been successfully subjected to review from our ISO 9001:2015 certification body. An excellent management system tool. The only problem was that people were not ‘instinctively’ using it.

Similarly, Siemens hosts and maintains a proficient social network tool (SSN), which is accessible to all employees. In essence, this tool provides a wonderful opportunity to effectively communicate a whole raft of information eg, best practice, lessons learned, training events etc. Again, the problem was that there were only a hard-core group of people who used it.

So back to the question: How can we create the desire for people to want to use a tool, follow a process, continually improve etc? After a ‘meeting of minds’, we developed the following blueprint to take forward:

Put yourself in your targeted audience’s shoes. Ask yourself: If I was in the audience, what would I want to get from this? Whether consciously or subconsciously, it is human nature to ask: What’s in this for me? It really is about creating the ideal ‘win-win’ situation.

Use anecdotal evidence and experience wherever possible to endorse why a particular action needs to be done. Unless absolutely necessary, always resist making an unjustified ‘thou shall’ decree. Doing something because you’re told to does not match the motivation and commitment of doing something because you want to.

Tailor your anecdotes and presentation to your audience. This doesn’t mean dumbing it down. Where possible informalise it. Put a human face to it. Why not add a bit of humour?

In summary, engage with your audience. Make them feel relevant ie, a key part of the activity. As ‘users’, assure them that their voices count, are heard and actioned.

Implementing the quality blueprint

In early 2017 we were in the throes of developing a companywide quality induction presentation, which enabled us to implement the principles of the above blueprint. As a result, we now have a quality induction video, voiced over by one of our quality team members. The video provides an informative overview of the quality processes, pitched with humour, and at the right level of detail. To encourage adoption of the BMS, the induction features a working example of where to find the BMS and how to access it.

To achieve the desired impact of the blueprint, we needed a worthy vehicle to drive it. Coincidentally, we were planning our approach to the forthcoming World Quality Day (WQD).

Crossrail Ltd had fully embraced WQD, turning it into a World Quality Week (WQW), and in the last few years Siemens has actively participated in the initiative as a Crossrail contractor. In recognising that Siemens’ involvement in WQD has predominantly been through the Crossrail Project, we committed to implement our own WQW.

The Siemens Quality Management team met to agree on the approach that would allow us to achieve a successful WQW. The following key requirements were determined:

- Demonstrate top management commitment.

- Communicate a consistent quality message.

- Align the Siemens WQW with the CQI’s ‘celebrating everyday leadership’ theme.

- Promote use of the SSN as the main tool for communication.

Effective communication was deemed critical to the success of the WQW initiative. Once SSN was agreed as the medium, the corporate communications team were contacted to provide support.

Demonstrating Siemens’ top management commitment to both this initiative and quality, Siemens Mobility Managing Director and a number of the company’s rail automation executives were asked to record video messages stating what quality meant to them and the importance of quality to us all. Additionally, we recorded an interview with one of Crossrail’s quality representatives.

PowerPoint presentations contained recorded voiceovers and video to support the daily themes.

In the two weeks prior to WQW, we implemented multi-channel communications, including SSN, to raise awareness and the desire to participate in the WQW.

Due to day job priorities and other quality related events also occurring, a monumental team effort was required in the week prior to WQW to ensure the programme was ready.

World Quality Week 2017

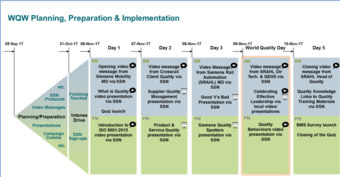

Monday 6 November: The Siemens Mobility Managing Director launched World Quality Week via SSN with a video presentation introducing Siemens WQW and what quality meant to him. This was followed by a video outlining ‘what is quality’. In the afternoon we had an informative voiceover presentation summarising the changes introduced by the ISO 9001:2015 standard.

Tuesday 7 November: An insightful video interview with a Crossrail quality representative about quality from the customer’s perspective was followed by a supplier quality assessment presentation. In the afternoon we had a product and service quality presentation.

Wednesday 8 November: A passionate video presentation from the Siemens Rail Automation Managing Director, conveying his thoughts on quality and why it was key to the success of operations, was followed by a Good vs Bad Quality presentation. In the afternoon we had a presentation creating awareness to the launch of the Siemens Quality Spotter form, which provides the workforce the opportunity to identify a nonconformity before its realised and actioned accordingly.

Thursday 9 November: A video message from the Director of Technology and Quality, Environment, Health and Safety, emphasising the importance of quality related training, was followed by a Celebrating Everyday Leadership presentation delivered by local quality managers across all sites. In the afternoon we had a voiced over Quality Behaviours video.

Friday 10 November: In addition to links to quality training materials and the BMS survey, we had a video message from our Head of Quality summarising the week’s events and re-emphasising the need for quality to be ‘right first time, every time’.

World Quality Week rewards

The Siemens WQW initiative proved to be an unprecedented success for the following reasons:

- Demonstrating top management commitment: In supporting the WQW initiative, top management demonstrated their commitment to quality via the video messages that they took time to record. We also had positive engagement from a number of other top management.

- Quality awareness: Raising awareness of Siemens’ quality processes, products and the required behaviours through the presentations.

- Chartered Qality Institute – Corporate Partnership: Cementing Siemens Corporate Partnership with the Chartered Quality Institute, particularly through Thursday’s leadership presentation.

- Promotion of the SSN: This campaign encouraged more than 220 personnel to follow the 55 first line #WQD and #WQW posts. The videos were viewed by 700 people via the sharing platform.

- Quality profile: Siemens’ employees now know who their quality representatives are and, more importantly, there has been a positive change in the representatives being approached and consulted on quality matters.

- Business Management System: Follow-up surveys on the Business Management System have identified the need for further BMS training and improvement opportunities.

- WQD Celebrating Everyday Leadership: More than 300 people attended the Celebrating Everyday Leadership presentations.

- Employee feedback: The WQW campaign received positive feedback via the SSN, which aptly demonstrated that the quality team effectively engaged the Siemens workforce and not just in the Mobility division, as a number of the attendees/viewers resided in other divisions and countries eg, Brazil, Germany etc.

- Siemens recognition: The unprecedented success was recognised by Siemens’ top management, who nominated the WQW team for the Siemens Champions Award. To date, the nomination has successfully been awarded bronze and silver status. Additionally, the Siemens WQW team has also been nominated for the prestigious Werner Von Siemens prize.

Quality World

Get the latest news, interviews and features on quality in our industry leading magazine.