Katana, Kaizen, and Deming's quality teachings in Japan

Progress indicator

Continuing the 'Exploring hidden dimensions' series, IRCA-certified Associate Auditor and International Project Quality Lead Rasoul Aivazi explores two foundational quality concepts – Monozukuri and Kaizen.

Rasoul Aivazi is a committee member of the CQI Audit, Deming, and DT special interest groups.

Ten years ago, my research into Katana swords led to a presentation at the Japan Society of Mechanical Engineers’ 2014 Mechanical Engineering Congress, at Tokyo Denki University, during the American Society of Mechanical Engineers’ Japan Section session. This experience led to me being captivated by the traditional advancements in Japanese swordsmith quality.

More recently, I have immersed myself in Dr W. Edwards Deming’s quality teachings, which revolutionised Japan and led to global quality leadership, total quality management (TQM), and manufacturing systems.

Viewed through the lens of Japanese cultural quality, this article explores the profound connection between Katana craftsmanship, the philosophy of Kaizen, and Deming’s quality principles.

Cultural quality: the bedrock of Japan’s recovery and industrial progress

Japan’s post-war recovery and development into a global economic powerhouse was driven by cultural quality, encompassing Kaizen, Deming’s quality teachings, innovation, and cultural resilience.

Examining 10 key dimensions of how culture shapes quality in Japan, we identify the concepts shown in Table 1 below. In Part 5 and Part 6 of this series, we examined #3 Kodawari through to #10 Hoso of the Table 1.

In this article, and part 8 next month, we turn our focus to the first two concepts—Monozukuri and Kaizen—illustrating them through an iconic example of the Japanese sword, Katana - and Deming’s quality teachings in Japan.

"Creating a Katana requires the mastery of techniques passed down through generations of skilled swordsmiths, who dedicate years to perfecting their craft."

These concepts are deeply ingrained in the Japanese psyche and contribute significantly to the country’s reputation for quality. When embraced and harnessed effectively, they become catalysts for professional success. Among these, Monozukuri and Kaizen stand out as fundamental.

Companies such as Toyota and Sony adopted Kaizen, enhancing productivity and product quality significantly. Deming’s teachings emphasised statistical quality control and continual improvement, resonating with Japanese cultural values and the Kaizen philosophy.

Table 1: The 10 cultural quality concepts influencing professional success in Japan.

Innovation and technological advancement: These were key drivers of Japan’s economic growth. Significant investment in research and development led to breakthroughs in electronics, automotive, and manufacturing. Companies such as Sony and Toyota became global leaders, synonymous with quality and innovation.

Cultural resilience and adaptation: These played a crucial role in Japan’s recovery. The Japanese demonstrated remarkable adaptability, embracing new technologies while preserving their cultural heritage. The concept of Ganbari (Kanji 頑張り: Hiraganaがんばり), literally meaning perseverance and hard work, encapsulates the Japanese spirit of resilience, essential in rebuilding the nation. Japan’s transformation is testament to the power of cultural quality, exemplified by Monozukuri and Kaizen, and collective effort in achieving success and overcoming challenges.

Katana: a testament to Japanese swordsmith quality

The katana (刀: かたな) is an iconic, traditional Japanese sword, a symbol of unparalleled craftsmanship and the aim for excellence. Creating a Katana requires the mastery of techniques passed down through generations of skilled swordsmiths, who dedicate years to perfecting their craft. The pursuit of excellence is deeply ingrained in their work, with each Katana regarded as a unique work of art.

This unwavering dedication to quality and relentless aim for perfection aligns with the principles of continual improvement. The creation of a Katana involves a thorough process using a specialised Japanese steel called tamahagane (玉鋼:たまはがね), the traditional steel used in the forging of Japanese swords.

Tamahagane is made from iron sand, which contains carbon. The carbon originates from charcoal, which is layered with the iron sand and serves as the heat source for achieving high temperatures and a required component in the smelting process.

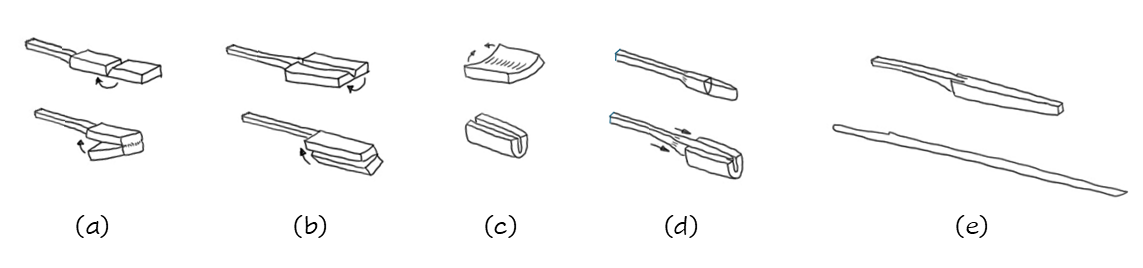

This intricate process involves multiple cycles of folding and forging (hammering) to refine the steel, enhancing the quality of both the core and jacket material (Figure 1). When a softer core steel, prepared, then a hard jacket steel is worked around the softer core steel (Figure 2).

Figure 1: Folding the steel bar over, hammering and flattening:

a) Folding lengthwise and preparing the core steel; b) folding widthwise; c) folding the steel into a U-shaped jacket; d) the hard jacket steel worked around the core steel; e) the core-jacket steel forged and hammered into the final form of the katana.

Figure 2: Hard jacket steel is attached around the core steel.

Discussion of Katana, Kaizen and Deming’s Quality Teachings in Japan will be continued in Part 8 of this series.

Acknowledgement: This part of the series has undergone review and comment by the distinguished international experts, each of whom has either resided in or conducted in-depth studies on Japan, or are of Japanese nationality: Richard Brett, Hiroyuki Iwamoto (岩本博之), Ryo Kanno (菅野亮), Shinya Watanabe (渡邉慎也) and Toshihiro Koga (古賀稔広). The author acknowledges and sincerely values the significant contributions and expertise they have provided. I am very grateful to all of the people who have lit my way on this journey. Any mistakes are entirely my own.

Want to lean more? Join a CQI SIG

The CQI 'special interest groups (SIGs) cover a wide variety of topics and specialisms. To find out more, visit our website.

Quality Careers Hub

Exclusively for members, the CQI’s Quality Careers Hub is designed for every career stage. So whether you’re just starting out, ready to move on or up, or looking to build on your experience, there are many ways to progress.

Quality World

Get the latest news, interviews and features on quality in our industry leading magazine.