The (many) Rs of sustainability

Progress indicator

Once upon a time, as the story goes, sustainability had three Rs. These were reduce, reuse and recycle, which set out a simple, accepted arrangement to control waste. Then came an explosion in the Rs, with more joining the original three, each providing a specific strategy to control waste within a framework of a product lifecycle.

There also appeared Rs for a framework of management of waste which, collectively with the lifecycle Rs, produce a robust arrangement for effective waste control.

The aim of the Rs is to prevent sending anything to landfill. Understanding what each R is, when to apply and employ them makes for a very effective management of resources used. This, as will be seen, is applicable to every industry.

What is waste?

Under ISO 14001 and the EU Waste Framework Directive, waste is any substance or object that the holder discards, intends to, or is required to, discard. In Lean terminology, waste (Muda) is any activity or material that consumes resources but does not add value to the customer.

Waste is universal, applying equally to every industry that purchases anything that is not used in a final product. This includes people’s time as well as physical resource.

Understanding the definition of waste in business is important because it directly impacts efficiency, cost, value, compliance and sustainability goals. Understanding waste allows businesses to work smarter, reduce risk, and create more value for customers in lower pricing and stakeholders by greater profits.

Product lifecycle

Every material or product has a lifecycle of creation, use and disposal. This can be looked at either as a circular process (referred to as the circular economy) or a linear process using a timeline.

"For quality professionals wondering where to start with sustainability, a quick understanding can be gathered by what is in bins, skips or what gets collected from the premises."

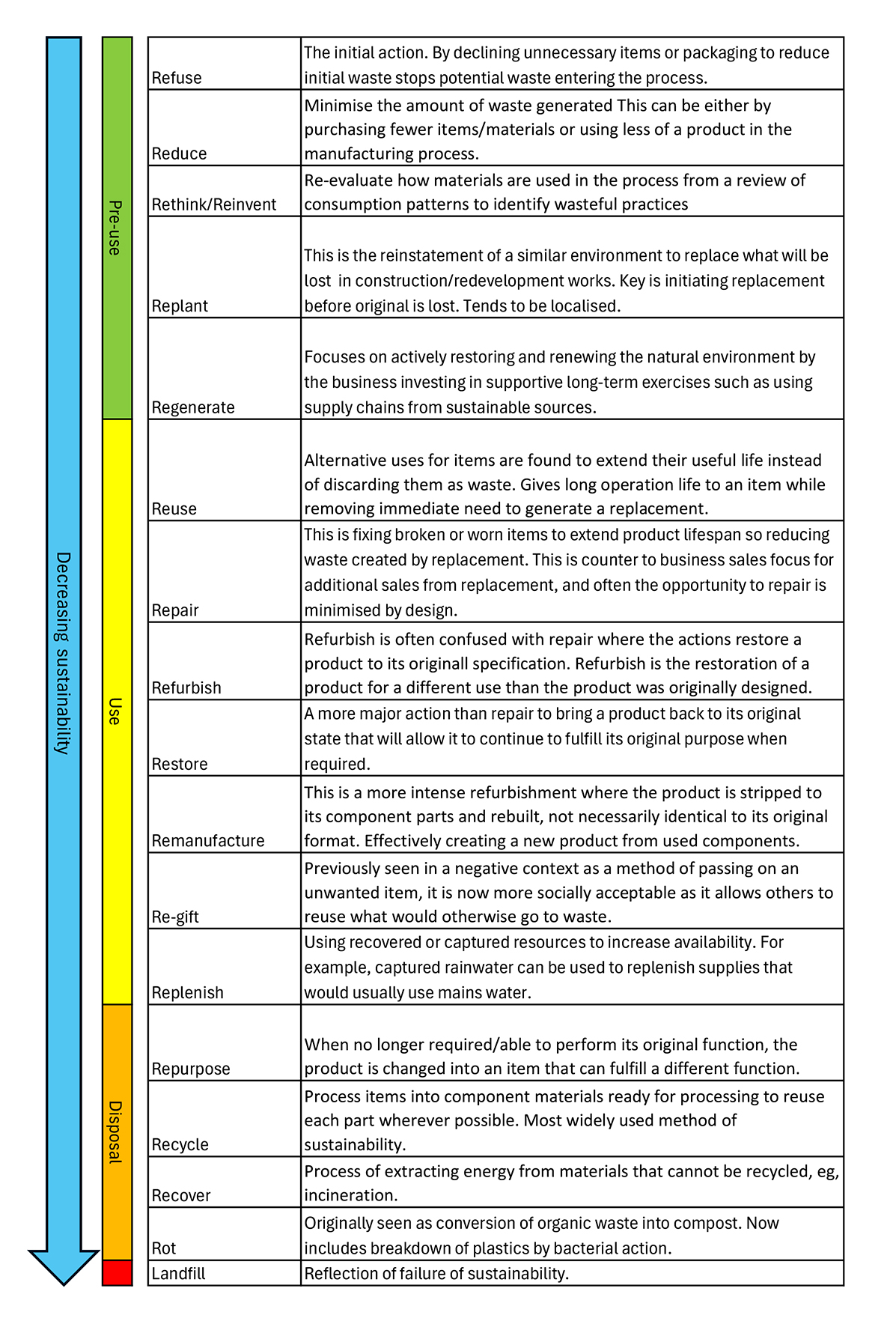

There are three distinct areas in the lifecycle, into which the various Rs can be allocated for maximum effect.

Pre-use: the activities that design out the potential waste before the product is brought into existence or use.

Use: the activities that provide for the prevention of waste when the products are still in a functioning state.

Disposal: the period of time where a product has finished its useful life, and the Rs represent those possible actions to prevent its disposal as landfill. Each of the R strategies has a most effective time to be applied for maximum benefit to be achieved. When applied to a linear timeline, the result is as shown below.

The management Rs

In any business, the role of the management team is critical in allowing sustainability benefits to be realised. Identification of potential savings is always a critical factor along with the benefits to the business image that a positive approach to sustainability can bring.

In line with the Rs, there are three that can be identified as management-led actions. These are respect, responsibility and re-evaluation.

Respect: is the understanding that resources are not infinite and getting the most from what is available is critical for any business. All resources within a business must be paid for, so getting value from these is paramount.

Responsibility: reflects how a business allows its staff and contractors to contribute positively to sustainability actions. While individual actions are important, having a positive framework in place to allow the implementation of sustainability actions is always beneficial to the business.

Re-evaluation: is the management function of how the business regularly reviews the effectiveness of its sustainability activities. Not everything needs to be reviewed with the same frequency, but programmed checks ensure current systems are effective and also identify areas for possible improvement.

Applying the Rs

Sustainability is a mechanism to control waste, and so the application of any sustainability initiative is to identify waste and understand why it is being caused, and its influence on the overall operation of the business.

For quality professionals wondering where to start with sustainability, a quick understanding can be gathered by what is in bins, skips or what gets collected from the premises. This is often an easy place to start to gather examples of waste.

The first thing to consider for each type of waste is – why is it waste? This requires the use of root cause analysis tools. If you are uncertain which to use, start with the 5 Whys until you have confidence with more advanced techniques. The result needed is ‘why is there waste?’

For each example of waste, then consider which Rs could be applied to eliminate it, particularly waste going to landfill. This can be achieved by reviewing each R in turn and considering:

- Does this R apply?

- If so, how could we apply it?

- What would be the outcome we need to manage?

Note that, often, more than one R will apply, sometimes to different parts of the waste.

Example 1:

A hydraulic pump has failed and been replaced. While the pump was considered waste, after stripping it down to identify the cause of the failure (motor failure), the cast iron casing was found to be in good condition and suitable for reuse.

The electric motor windings had failed through broken-down insulation and so these were replaced as part of a repair. The failed windings were sent for stripping down to specific materials for recycling. As part of the refurbish, all the gland seals were replaced and had to be discarded to landfill as no recycle was available.

Don’t overlook applying the process to items already classified as waste and being managed eg, already separated out to recycle. Can these be addressed by more proactive sustainability Rs?

Example 2:

Perfectly good wooden pallets were found in the timber recycling skip, discarded as waste after being unpacked. To understand why they were there, a 5 Whys root cause exercise was undertaken. This identified that no-one on site was aware that the delivery company would collect the pallets free of charge on a subsequent visit. Site staff were instructed to stack pallets beside the timber recycle skip and these were all uploaded to the delivery lorry as part of the process.

By this stage, sufficient information is known about the waste, its origin and possible actions to eliminate or reduce. This then provides the information to initiate change in the management and operation of processes to encapsulate best sustainability practice into day-to-day operations.

Applying and understanding

By understanding and applying the various R strategies at the appropriate time, quality professionals can not only make their manufacturing processes more sustainable, but also more efficient and cost-effective.

Want to discuss this article with like-minded quality professionals?

Join the CQI's Sustainability network.

Quality World

Get the latest news, interviews and features on quality in our industry leading magazine.

The latest from the CQI Podcast

Listen to the Quality Impact podcast, where experts share insights on the evolving role of quality across industries.